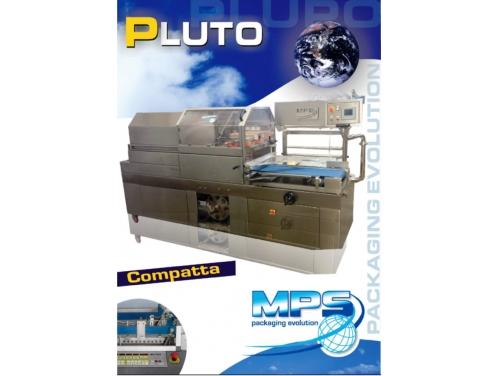

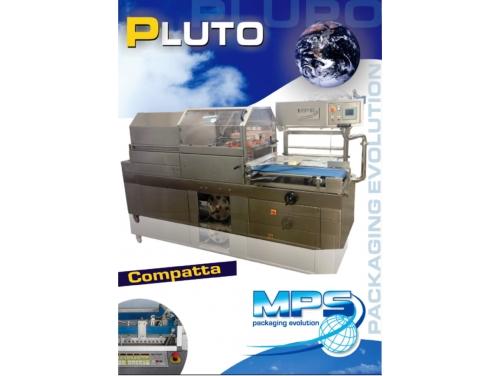

Macchina confezionatrice angolare automatica

ON REQUEST

- Double reel holder

- Hot-needle perforator

- Film blower

- Print centering photocell

- Motorized infeed belt width adjustment

- Automatic switch-on timer

- Pre-cut unit for easy bag opening

- Gas injection device

- Film runout sensor

- Increased infeed and outfeed belts Motorized belt guides above the product

- Thermal printing

- Pusher

- Pneumatic presser

- Sealing bar for thick seals (4mm with PE and PT)

- Film bending roller

- Barrier photocell

- Translating conveyor belts for small or round products

- Increased bar opening

Our technical office is available for further changes. For more options and modifications do not hesitate to contact our Technical department.

SHRINK TUNNEL

- Hot air oven designed for the heat-shrinking of flow-wrapped products. It can be used either with angular or other packaging machines. The tunnel is equipped with electric heaters that heat the air. A specific hot air recirculation system increases energy efficiency and shrinking power. It does not need any maintenance.

- The exclusive low turbulence hot air distribution system with heat recovery and uniform power distribution ensures significant energy savings.

- Electromechanical belt speed adjustment.

- Temperature regulation by an integrated proportional thermostat with extremely low deviation.

- Self-cooled electrical and electronic components. Safety systems according to EEC standards. Packing materials: Cryovac, PPT, PTE.